- info@roarkfab.com

- 317-852-3163

CASE STUDY

EB Welding used on small components for nuclear pharmaceuticals

A producer of radio-pharmaceutical therapies was building a cyclotron to accelerate and compound chemicals used in cancer detection and nuclear therapies. Because of the high degree of volatility with the pharmaceuticals being produced, the engineering specifications for the fabrication of metal parts used for the cyclotron were extremely rigid. All metal parts were exposed to high-heat/high-stress environments and the welds needed to hold in these conditions.

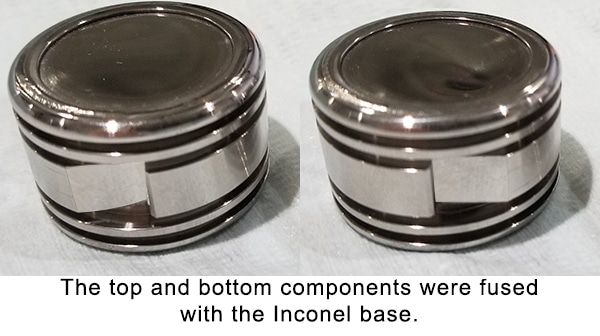

Solution: The customer needed five small Inconel components to be welded together to form a single part. That part would fit into an apparatus used to hold specific isotopes during production. Inconel is a nickel-chromium-based superalloy commonly used in high-heat applications where the integrity of the metal cannot be compromised. It is used in the nuclear industries for its resistance to corrosion and high strength, especially in extreme heat.

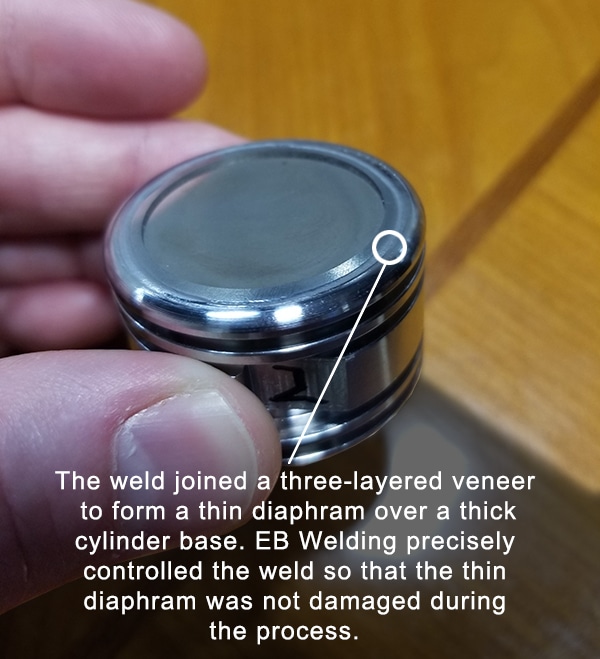

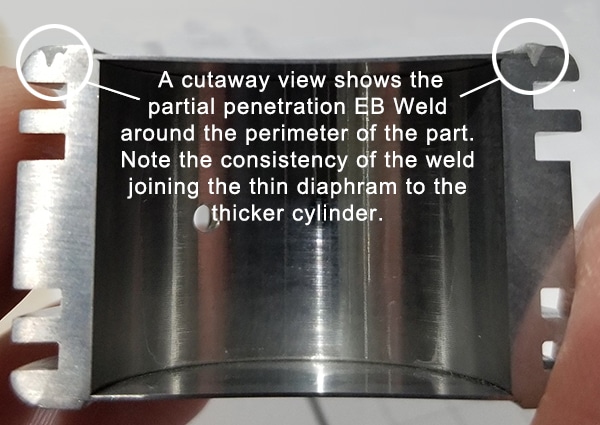

Inconel can be a difficult alloy to fuse together. It requires high heat to melt. In this case, the five components were manufactured with a light gauge metal. The customer needed a seamless weld that would only partially penetrate the thin veneer of the part and join it to the thicker cylinder base. High heat and a thin surface are the perfect combination for EB welding. The depth of the weld is programmed into a computer-aided system and is controlled incrementally, while the intensity of the electron beam is also regulated as it fuses the parts together. The result is a small, but strong seamless weld that is consistent across the entire part without compromising the thin diaphram on the top and bottom of the part.

Another aspect of this particular project made EB welding the perfect choice. In this case, contamination of the metal was a concern. The tight standards demanded that the welding take place in the cleanest environment possible. Because of the nature of radiotherapy drugs, any slight microbial contamination would render the part useless. Roark Welding uses vacuum chambers to evacuate all extraneous gases before welding takes place. Roark Welding engineers also met with the customer in advance of the project to go over specific requirements to ensure that proper standards and procedures were met. Roark Welding is ISO 9001 Certified, which was a quality requirement of this customer.

Roark Welding was able to meet the specifications of this job and weld the Inconel parts to the satisfaction of the customer. For more information on EB welding regarding high-heat/high-stress metals, or metal fabrication requirements within your industry, contact Roark Welding at 317-852-3163, ext 901 or info@roarkfab.com.