- info@roarkfab.com

- 317-852-3163

CASE STUDY

Electron Beam Welding used for Rocket Exhaust Nozzle Assembly

An aerospace contractor needed a machined component to use in the forming of a rocket exhaust nozzle. This tool was used to form the inside dimension of the nozzle through thermal expansion of the metal against the OD of the tool. The tool was provided in two structural castings that needed to be welded together to form one large piece.

Solution: This project provided several difficult welding tasks. First, there was the size and weight of the parts used in this particular welding application. The two parts weighed in excess of three tons and, when combined, were over six feet tall. From a manufacturing point of view, casting this piece at this size is both pricey and time consuming. Welding the two pieces together saved both time and kept cost down. However, maneuvering the two parts and holding them in position was challenging for any welding application, but EB Welding proved to be the best way to handle the two components. Roark Welding has the ability to weld very large and heavy metal parts. Their EB Welding facilities include some of the industry’s largest EB Welding CNC vacuum chambers, which can also be expanded to accommodate extra-long parts. From an accuracy standpoint, the parts were held in place on a rotary station that is engineered to hold a true center and programmed to move in conjunction with the electron beam.

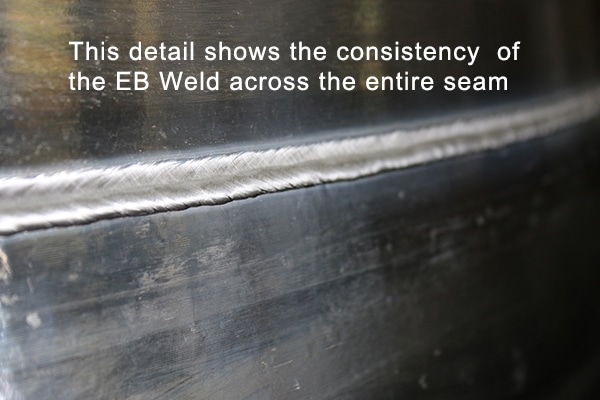

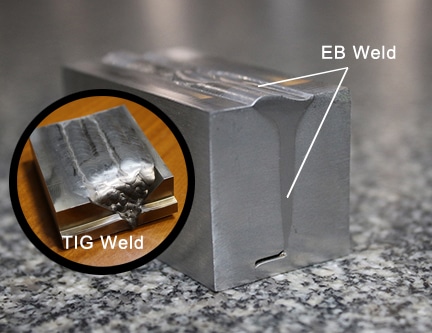

The second challenge was the depth of the weld that would penetrate most of the OD of the tool, but not penetrate to the ID. The walls of the two parts being fused were 1.25”. The weld depth needed to be 1”. Traditional welding techniques would have required a wide weld prep v-groove to penetrate to this depth. Other computer-aided welding techniques, such as laser welding, are not able to handle welds at this depth. EB Welding makes a much smaller channel than traditional welding techniques and is able to penetrate deep into the metal. In addition, it is very precise, holding tight tolerances on the depth of the weld across the circumference of the tool.

The third challenge were the rigors of high heat used with this tool. Since the tool was being used for forming metal through thermal expansion, the weld had to withstand the high heat of the process. EB Welding is the perfect welding option for high strength integrity in high stress environments. The depth of the weld is held consistent across the entire seam because the electron beam is computer controlled. This eliminates weak points in the weld due to human error.

The customer was very pleased with the welding on the rocket nozzle forming tool. If you are dealing with large metal components and need welding services, contact us about EB Welding. Contact Roark Welding at 317-852-3163, ext. 901 or info@roarkfab.com.