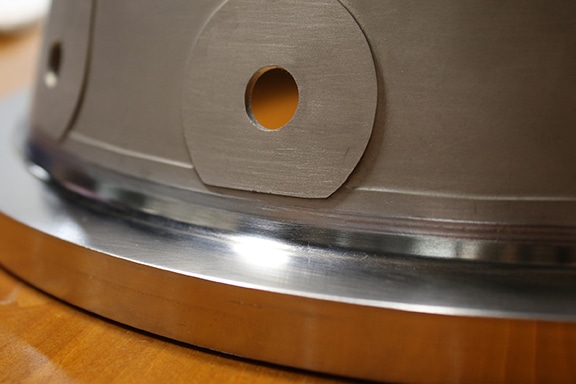

Titanium missile case uses EB Welding for partial penetration welds and complex angles.

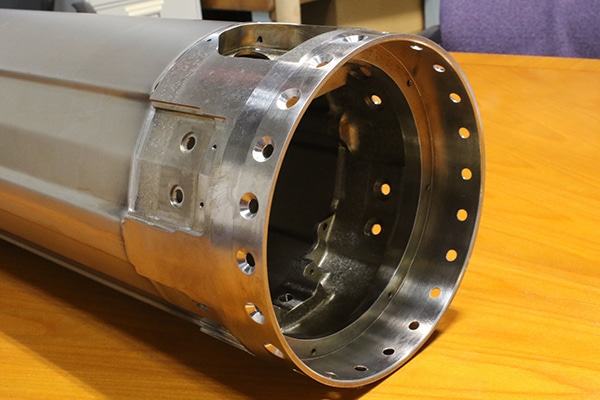

A manufacturer of helicopter engines needed three machined components of a turboshaft combustion chamber welded together. Since the precise mixing of gases and fuel are critical to proper combustion, the welds needed to hold close tolerances to keep the chamber airtight and be able to withstand the high heat of burning fuel.

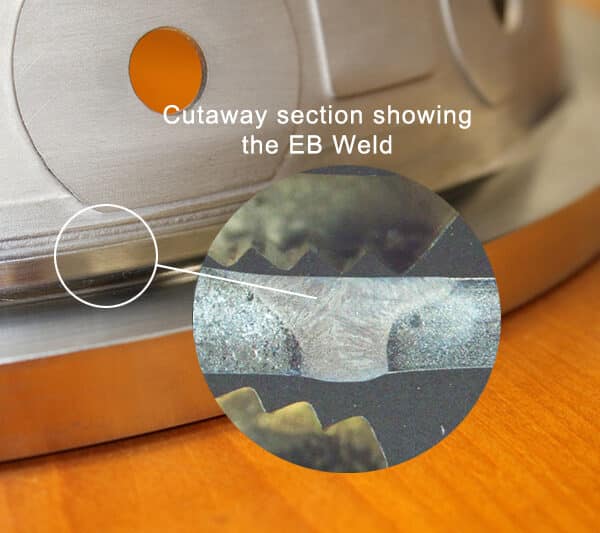

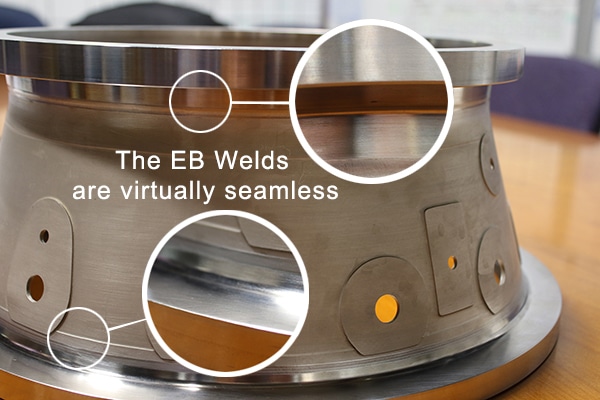

Solution: Nickel-based superalloys are used in high-heat applications. Welding these alloys can be tricky. For instance, weld joints for nickel alloys can develop hot cracking as the weld cools and shrinks. In this case, the weld had to be free from these kinds of defects. If there are other contaminants present during the welding process, cracking can also occur. Gases or other extraneous molecular elements can cause problems over time and cause oxidation. Using EB Welding makes sense for a number of reasons. First, EB Welding works very well with advanced nickel alloys. It facilitates superior cohesion to the materials. It cuts a very small weld path – so small that a secondary material is not needed to fuse the two pieces. Second, the problems of cracking through shrinkage of the weld in the cooling process is eliminated because EB Welding does not use a filler material like traditional welding. Third, the weld holds because the weld joint is deeper than conventional GTAW welding techniques. Fourth, EB Welding is performed in a vacuum. Where other welding techniques use an inert gas to cover the welded area, EB Welding eliminates gases, such as oxygen, in the vacuum chamber. This eliminates the chance of oxidation.

You might be wondering why this helicopter part was built by welding three components together. Wouldn’t you eliminate any problems if you simply milled one part instead of three? While that might be true, from a practical standpoint, one large part would cost you more to produce than three sections joined together with an electron beam weld. EB Welding gives you the flexibility to engineer complex mechanisms with the assurance that the weld will hold in the most extreme operating conditions. Since it is digitally assigned, the depth of the weld can be adjusted for differing thicknesses. It can also weld complex, three-dimensional parts, holding to very tight tolerances.

In the end, the customer was very satisfied with the welding on this combustion chamber. If you have questions about EB Welding on your parts, especially if you are dealing with high-stress metal parts, contact Roark Welding at 317-852-3163, ext. 901 or [email protected].