- info@roarkfab.com

- 317-852-3163

CASE STUDY

Electron Beam Welding used on particle accelerator cavities

The Facility for Rare Isotope Beams (FRIB) at Michigan State University is a world-class nuclear science research facility. It contains a 1,400’ linear accelerator to smash atoms – elemental isotopes utilizing filters to strip the wanted from unwanted atomic particles. Once isolated, these particles are aimed at a target and the impending collision is studied and analyzed.

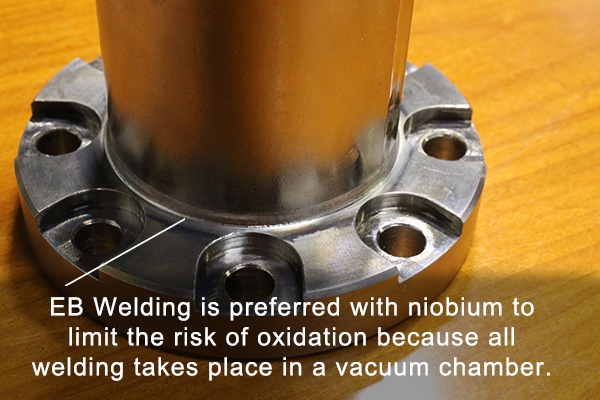

The engine/cavity that accelerates these particles is made from elements that allow for the free flow of electricity over its surface with very little resistance (superconductors). In this case, they are built with niobium. These niobium cavities are formed and then welded at the edges. The requirements for the surface finish, profile of the face and root of these welds is tightly controlled, as is the handling of the welded materials.

Solution: EB Welding is the most successful joining process when dealing with niobium and other elemental metals. From a metallurgic standpoint, one of the issues of welding niobium is that it oxidizes when its temperature is raised above a threshold and exposed to atmosphere. Niobium has a melting temperature of 2,477ºC. The EB Welding process is very controlled. It applies the required amount of energy (Joules) to a tightly defined area of the parts being welded – be that surface or joint weld. Since EB Welding happens in a vacuum chamber, the risk of exposing the niobium to any kind of atmospheric contaminant is greatly diminished. After each weld is complete, the parts are given time to cool down slowly. The end result is a small and virtually seamless weld.

At the conclusion of this project, FRIB was very pleased with the performance of the welded cavities. Roark Welding was able to meet all the performance demands of this project. If you are looking for a process to join sensitive metals, consider EB Welding, which provides digitally controlled welding. It delivers greater energy and mechanical controls than traditional welding processes. For more information, contact us at info@roarkfab.com or call us at 317-852-3163, ext. 901.